London, UK

HEATHROW AIRPORT

HOW HEATHROW MADE 55% ENERGY SAVINGS WITHOUT COMPROMISING LIGHTING PERFORMANCE

With an average of 200,000 passengers arriving and departing per day, Heathrow Airport is one of the busiest airports in Europe. The focus of the project was to provide a high quality energy efficient LED scheme specific to the requirements of Heathrow Airport, with minimal disruption to the airport’s meticulous schedule.

All the FL800R fittings were manufactured in Ware, Hertfordshire on a strict schedule. The advantage to producing the lanterns ‘in house’ meant CU Phosco could react quickly to operative feedback on site and alter production to improve the installation process. For example, the use of a plug and socket system was included in the lantern design. As a result the majority of the wiring was completed in the control environment of the factory, minimising time on site.

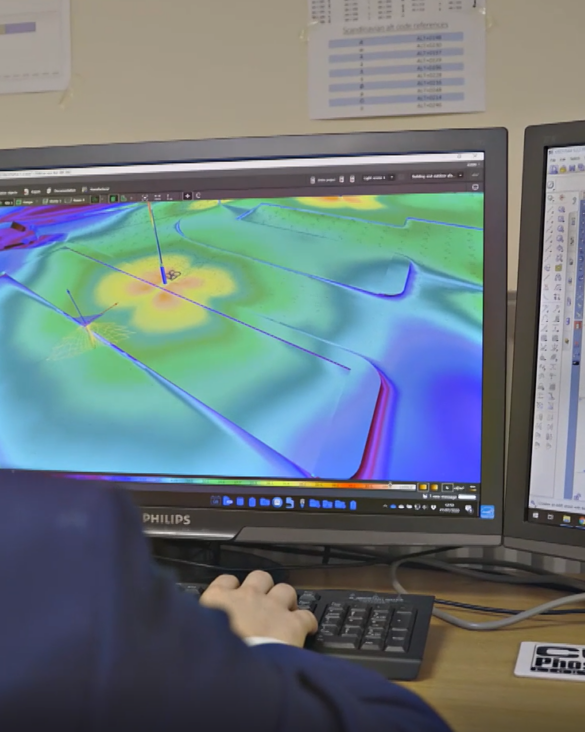

The difference in light quality from Sodium to LED is evident across Terminal 5. The FL800R provides exceptional control minimising obtrusive light, glare and upward light without compromising the lighting performance. This means the conversion has not only created an improved environment on the stands, it has provided a substantial energy saving.

RESULTS AND BENEFITS

It became apparent from the start of the project that CU Phosco had to deliver a flexible and streamlined system to operate efficiently in the strict working window given each night when flights stopped. Therefore CU Phosco adapted the FL800R product to reduce the installation time. Each procedure was rigorously scrutinised so that all activities were completed on time.

The outcome of the project and a subsequent tender process has resulted in CU Phosco being appointed by Mitie Facilities Management on behalf of Heathrow Airport Ltd to carry out LED replacements on the remaining stands at Terminals 1, 2, 3 and 4.